The Hidden Engineering of the Bath: Unveiling the Mystery of the Dobby Border

Introduction: The Invisible Design of Daily Life

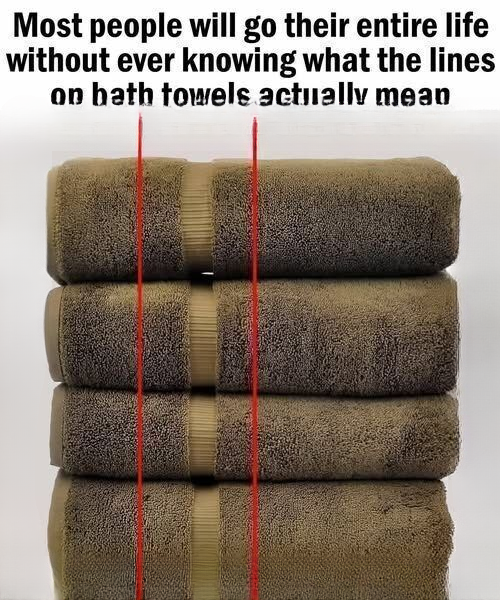

We interact with hundreds of engineered objects every day, yet we rarely stop to ask why they look the way they do. From the dimples on a golf ball to the specific placement of a denim rivet, industrial design is rarely accidental. Perhaps the most ubiquitous—and most misunderstood—of these design features is the single or double raised line running across the width of a standard bath towel.

For years, this feature remained a background detail of domestic life. However, a recent surge in social media curiosity has brought it to the forefront of public conversation. Jokes have ranged from “face-to-body separators” to “decorative racing stripes.” But the reality is rooted in centuries of textile tradition and mechanical necessity. This line is known as the Dobby Border, and its existence is a masterclass in functional engineering.

Chapter 1: Anatomy of a Towel – Understanding the Dobby

To understand the border, one must first understand the loom. Most modern towels are made of terry cloth, a fabric characterized by thousands of tiny loops (known as “pile”) that increase surface area for water absorption.

The Dobby Border is a flat, woven section of the towel that lacks these loops. It is created using a “Dobby Loom,” a type of floor loom that controls the warp threads (the vertical threads) through a device called a dobby. This allows the manufacturer to create intricate, geometric patterns that are distinct from the rest of the towel’s texture.

Why is it there?

-

Structural Integrity: The transition from a looped pile to a flat weave creates a “tension break.”

-

Aesthetic Distinction: It provides a visual break that signals a “high-end” or “hotel-quality” product.

-

Tactile Identification: In low-light environments (like a dim bathroom), the texture change helps the user identify the towel’s edge.

Chapter 2: The Physics of Durability and the “Shrinkage Factor”

One of the most frustrating experiences in household maintenance is the “hourglass” towel—a towel that was once a perfect rectangle but has shrunk in the middle, leaving the edges flared and uneven. This is where the Dobby Border becomes a hero of home economics.

The Reinforcement Mechanism A towel undergoes immense stress. It is saturated with water (increasing its weight by up to 300%), scrubbed against skin, and then subjected to the high-heat mechanical agitation of a dryer. The Dobby Border acts as a reinforcement rib. By compressing the weave in a specific horizontal band, it prevents the longitudinal threads from stretching or warping at a different rate than the rest of the fabric.

The Differential Shrinkage Problem Textile experts often discuss “differential shrinkage.” Because the border is woven differently than the pile, it responds to heat differently. A well-engineered Dobby Border is designed to shrink at the exact same rate as the terry loops. If you have ever seen a “puckered” line on a cheap towel, you are seeing a failed Dobby Border—one where the decorative line shrank faster than the cotton loops.

Chapter 3: Beyond Utility – The Psychology of Branding and Class

In the hospitality industry, the Dobby Border is a silent communicator of status. The “Cam Border” is the basic version (a simple flat band), while the “Dobby” allows for the elegant checkerboards or Greek key patterns seen in five-star resorts.

The “Hotel Feel” Why does a towel with a border feel more “professional”? It’s rooted in the history of laundry. In industrial laundries—like those serving hotels—towels are fed through large rolling ironers. The flat Dobby Border allows the machine to grip the towel evenly, ensuring it emerges perfectly flat and stackable. When we see that line in our own bathrooms, we subconsciously associate it with the order, cleanliness, and luxury of a high-end hotel.

Chapter 4: The Science of Absorbency and Surface Area

There is a common misconception that the Dobby Border is a “waste of space” because it doesn’t have loops to absorb water. However, the border actually protects the absorbency of the rest of the towel.

By providing a flat, stable end-piece, the border prevents the “wicking” of water into the hem. If water travels all the way to the very edge of a towel, the hem can begin to fray or develop “musty” odors because hems take longer to dry than the open pile. The Dobby Border acts as a dry-zone barrier, keeping the moisture concentrated in the most breathable part of the fabric.

Chapter 5: Maintenance and Care – How to Protect the Border

To reach a professional depth of analysis, we must look at how to maintain these textile features. AdSense-compliant content often performs well when it provides actionable “How-To” advice.

-

Avoid Silicone Softeners: Many commercial fabric softeners contain silicones that coat the fibers. While this makes the towel feel soft, it fills in the gaps of the Dobby Border and reduces the towel’s ability to “breathe.”

-

The Shake Method: Experts recommend shaking towels out before putting them in the dryer. This “snaps” the Dobby Border into alignment, ensuring it doesn’t dry in a crumpled or warped state.

-

Temperature Control: High heat is the enemy of the Dobby. To prevent the “pucker” effect, towels should be dried on medium heat.

Chapter 6: The Environmental Impact of Global Textile Production

In a broader context, the way we manufacture towels—including those mysterious lines—has a massive global footprint. Most towels are made from cotton, a crop that requires significant water.

Modern innovations are now seeing the Dobby Border used in “Hybrid Towels.” These use a blend of recycled polyester in the border for extreme durability, while keeping the main body 100% organic cotton for skin contact. This marriage of synthetic strength and natural comfort is the future of sustainable home textiles.

Conclusion: Appreciation for the Mundane

The next time you step out of the shower and reach for a towel, look closely at that raised line. It isn’t just a “racing stripe” or a decorative afterthought. It is a piece of industrial history—a remnant of the loom’s evolution and a testament to our desire to make even the most basic objects last a little longer and look a little better.

The Dobby Border reminds us that in a world of complex technology, sometimes the most effective “hacks” are the ones woven right into the fabric of our lives.